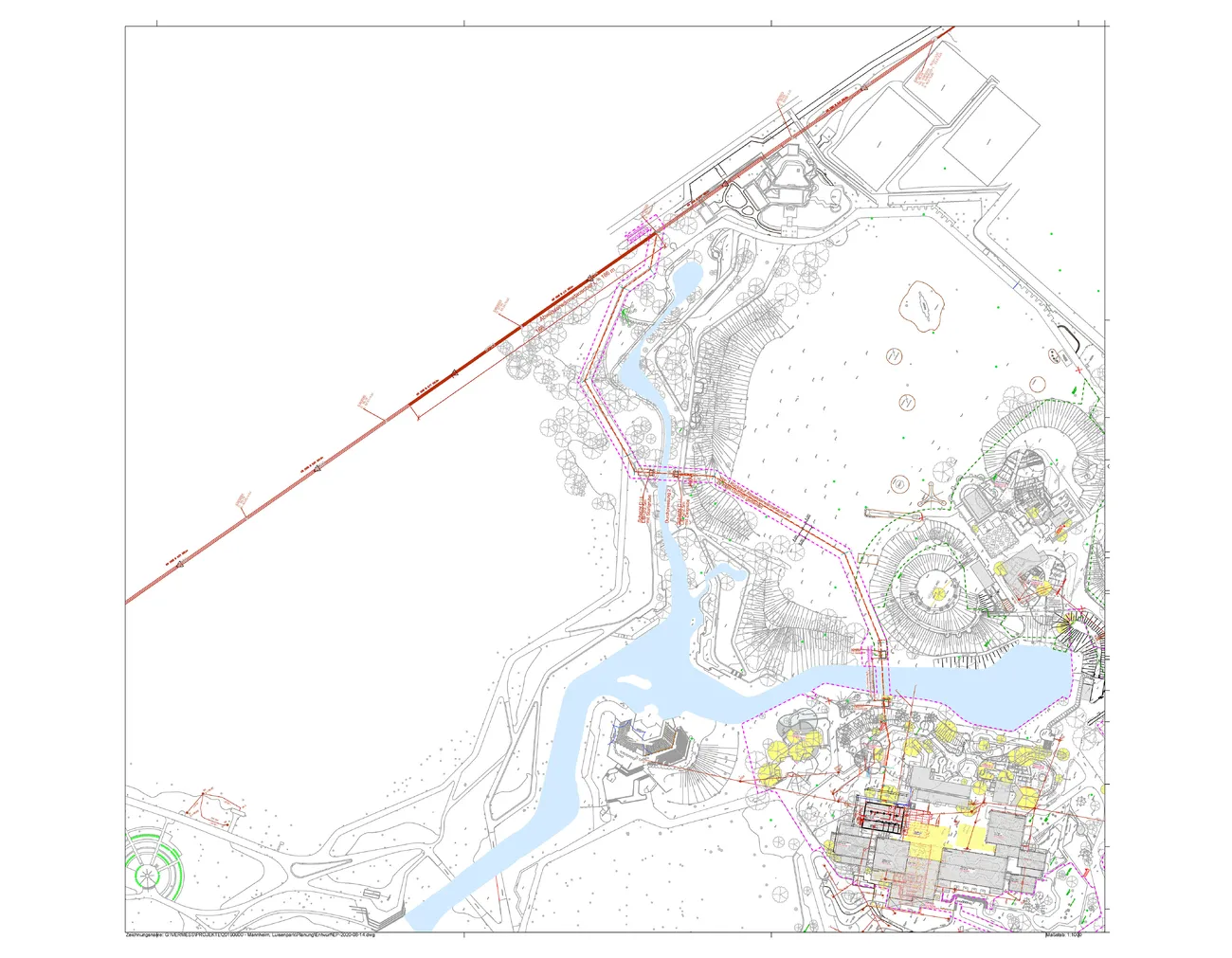

Nouveau Centre Luisenpark, Mannheim, Allemagne

As part of the redesign of the city's largest park, several new buildings with different uses were being built. Pavilions remain single-story above ground and have green roofs. The Central building cluster is divided into the multifunctional building with restaurant and an aquarium, a walk-in aviary, and a penguin enclosure with technical and animal care spaces as well as a back-of-house building with restrooms. Construction for this phase was completed for the exposition BUGA 2023. Further buildings are planned in a second expansion phase.

The energy and ventilation concept of the buildings combines energy efficiency with the highest possible thermal and visual comfort. It fulfills the desire to provide the best quality of stay for visitors, employees, and animals while at the same time using as little energy as possible. The solutions used are environmentally friendly and make use of renewable energy. The new buildings are mechanically ventilated. Given space constraints, the aquarium area is conditioned via the ventilation system. A separate ventilation system is used for the kitchens. The low-tech strategy of ceiling fans augments user comfort when indoor temperatures are high by increasing the air movement in critical rooms. When outdoor conditions are optimal, the large sliding windows of the restaurant can be opened to passively condition the space and reduce energy demand. The buildings are primarily heated and cooled via floor activation, supplemented by mechanical ventilation.

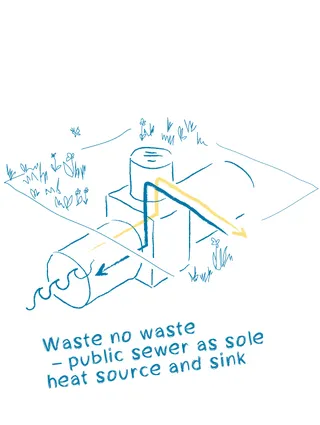

The heat source and sink of this project is the wastewater from a public sewer adjacent to the park, into which a wastewater heat exchanger system (WWHE) has been installed. Throughout the year, the wastewater has relatively high temperatures of between 10 and 20°C (50°F–68°F), so that a heat pump can provide the required thermal energy very efficiently with comparatively low power consumption. The technology used here, a standardized stainless steel heat exchanger, can be easily installed along the floor in existing sewers. The wastewater flows over and, if necessary, under the heat exchangers. A separate flow of liquid, which is colder than the wastewater, passes through them and heats up. The now warmer water flows to the building, where a heat pump extracts heat energy and uses it for heating, which cools the water down again to allow it to flow back to the heat exchangers in a closed circuit. Although the heat extraction cools the wastewater, which has an average temperature of 15°C (59°F), its temperature recovers through further inflows and the ambient heat from the ground. Depending on municipal regulations, wastewater can be cooled down to 5°C (41°F). To cool the building in the summer months, the reversible heat pump reverses the process, and the wastewater is used to remove the excess heat extracted from the building. A continuous flow of wastewater is a prerequisite for reliable operation. The property to be supplied should therefore be within reach of a sewer system with a sufficiently high flow rate. Suitable locations can be found in towns and municipalities with a population of 5,000 or more. Both conditions are met for this project.

Emergency supply is important if, for example, there is pipe damage in the WWHE or in the event of structural damage in the duct. But even in the event of a technical defect with complete failure of the heat pump, the emergency supply of heating and cooling to the aquarium must be guaranteed to keep the temperature in the tanks at an acceptable level for the plants and animals, including corals. An emergency supply is possible via the network of the central building cluster, heat can be fed in from the Luisenpark central heat plant to the warm water aquariums or cooling can be provided from the well into the central building system to feed the penguins basin. Another safety feature in the system is the large water volume of the WWHE, including the supply lines, which buffers short-term fluctuations, e.g. during the course of the day. In addition, due to its design without moving parts and sensitive electronics, a WWHE is a solid, technically robust, and therefore very fail-safe system that supplies energy in an environmentally friendly way.