Promega Administration and Logistics Center, Walldorf, Germany

The building essentially consists of two parts. The logistics area houses deep-freeze rooms and cabinets, storage areas and technical equipment for goods packaging and dispatch as well as the production area of the subsidiary Terso. The administration area contains a conference area, a workshop, a canteen with staff kitchen and a fitness area in addition to the office space. The areas are grouped around a multi-story "marketplace" (atrium). A wooden support structure spans the open, three-story office area and offers approx. 100 employees a new workplace and sufficient space for expansion.

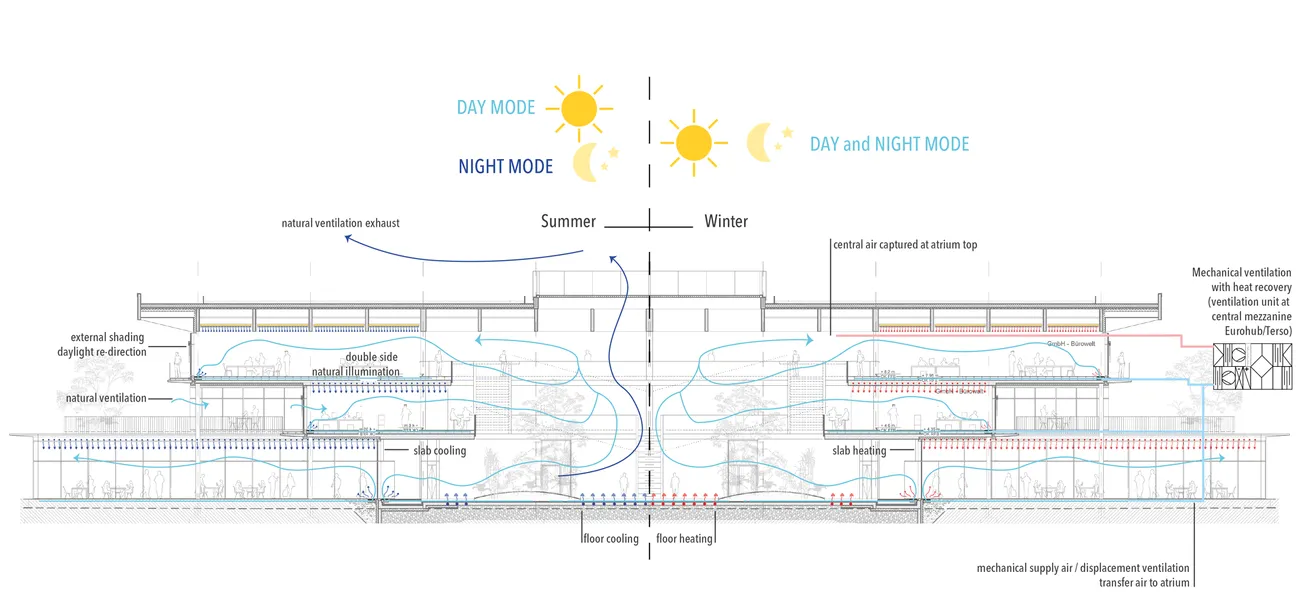

Open workplaces and informal meeting areas are assigned to the central, light-flooded and green atrium. It forms a natural chimney effect in the building and, with its roof openings, serves as a drive for natural ventilation, as well as for night air cooling during summer.

Mechanical ventilation supports thermal comfort and indoor air quality as required and is introduced into the work areas via comfortable displacement ventilation along the facades. The exhaust air is collected centrally in the atrium and fed to the ventilation unit for heat recovery. Behind the façade and in the atrium, which has been optimized for daylight inside, all permanently used areas are designed to make the best possible use of natural lighting at the workplace. The façade design guarantees thermal protection, and passively and actively regulates solar radiation via external venetian blinds.

The building is heated and cooled by means of a building component activation system (ground floor and 1st floor) or by heating/cooling ceilings (2nd floor). In the cafeteria and atrium, underfloor heating is also installed, which can also be used for cooling in summer. A geothermal field with 50 geothermal boreholes and a depth of 100 m / 328 f covers a large part of the building's heating and cooling requirements with the help of a reversible heat pump. A recooling plant is also available for emergencies. A gas condensing boiler serves as a second heat source to secure the heat demand. The logistics area puts high demands on the ventilation, since large quantities of CO2 have to be removed by packing in dry ice.

A photovoltaic system covers part of the building's electricity requirements. The design of the plant was based on the electrical planning for the basic electrical load to use as much of the own electricity as possible. All technical systems are designed for energy efficiency and are optimized in their interaction with the help of monitoring. The building is an example of modernity and efficiency with a high ecological quality.

2020 Hugo Häring Auszeichnung