Embedded energy and the iterative integrated design process of buildings

A conventional office building with effective, but highly complex technical systems, with high costs for control and maintenance and a high proportion of material-bound energy, is facing a plan which focuses on intelligent usage of carefully selected materials and saving energy and costs not only by radically simplified construction and manufacturing processes in operation, but by utilizing future-friendly resources while providing users with high-quality comfort: The office world of Alnatura.

In recent decades, research in the construction sector has focused on reducing the energy needs of building operations. As a result, buildings with a very low energy requirement in operation have emerged (such as passive houses), but their energetic effort for the establishment is not thematized, calculated or integrated into the conception. Such an approach leads to designs that can demand increasingly more systems engineering and special materials in the building. In this case, the entire energy expenditure for the construction of the building and its components can only be assessed retrospectively, after completion of the planning processes. Components with a high energy content in a total balance sheet are thus ignored during planning.

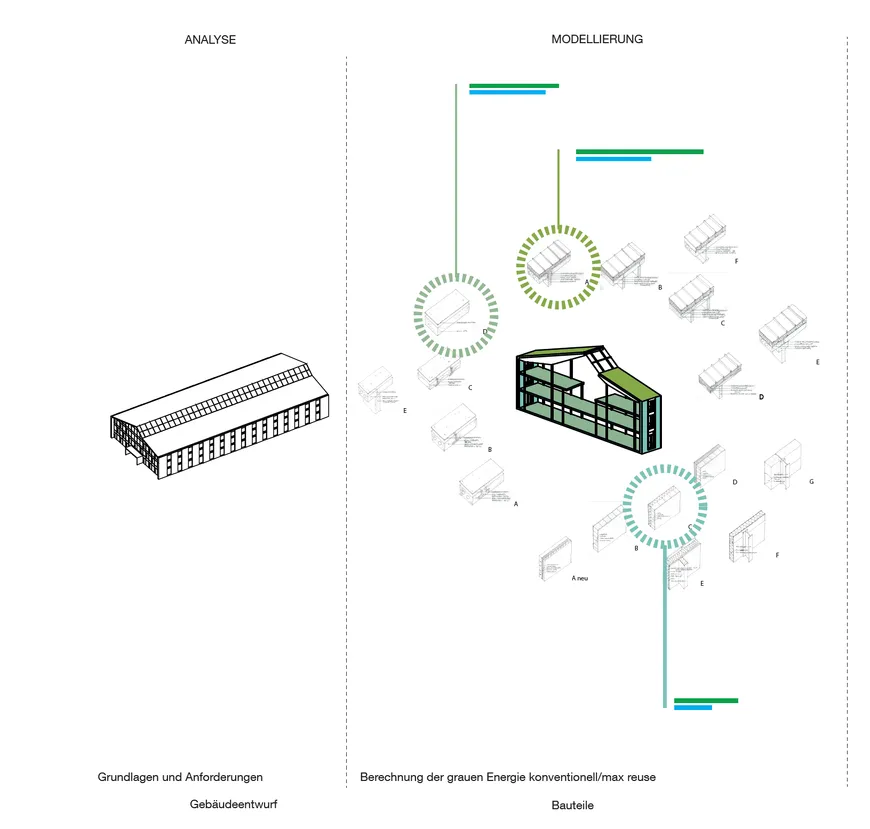

Taking into account "Embedded Energy" means calculating the amount of energy needed to manufacture, transport, store, sell, and eventually dispose of products. Consideration of life cycles of individual building components has only recently become meaningful. Strategies to minimize the portion of the embedded energy necessary for the building were evaluated in a research project on the development of strategies for the implementation of the embedded energy expenditure in the iterative integrated design process of buildings with the example of the head office “Alnatura world” in Darmstadt.

At the Alnatura Campus in Darmstadt, a project by architects Haas Cook Zemmrich, special attention was paid during the planning phase to the fact that passive measures minimize the amount of technical equipment and still meet the high demands on comfort for the working world. At the same time, the strategies adapted to the climate and requirements should guarantee a high degree of flexibility and a low effort for maintenance and overhaul, so that neither further embedded energy nor costs for new installations or additional technical installations are incurred.

Exposed storage masses are used for tempering passively by night cooling or actively by component activation. This leads to an increase in comfort as well as reduced energy consumption. The early consideration of the embedded energy in the planning phase of the preliminary design led to resource-saving solutions for the components chosen for construction. For this purpose, the dependency between the operating and embedded energy of the different variants is shown, without overriding the requirements for the indoor climate. As part of the project, different variants for the components were compared and evaluated with respect to embedded energy. The aim was to implement the variant with the lowest energy requirement after calculation.

The innovation of this approach lies in the radical simplification of construction and manufacturing processes. In addition to energy efficiency, the focus is also on developing a resource-optimized building. In order to achieve the governmental goal of a CO2 neutral building stock by 2020, implementation of the embedded energy aspects in the design process will be inevitable.

This required CO2 neutrality strives to generally avoid the emission of greenhouse gases in all sectors. This is already being demonstrated by a number of examples in the construction sector through the use of recyclable materials in terms of circulation-compatible materials, available energy systems, architectural measures and renewable energy resources.

The inclusion of energy in materials in the planning of construction and rehabilitation measures is becoming increasingly important. Growing energy prices and rising demand for fossil fuels make energy efficient systems inevitable. The concepts should offer environmentally friendly and more flexible construction methods. This requires not only the conversion to renewable energy sources to supply the technical systems and a reduction of the current energy consumption by up to 70%, but also the reduction of the total CO2 emissions.

This description of a holistic planning process was applied to the design of the “Alnatura Campus.” The aim was that the administrative building should provide a comfortable indoor climate through an optimized passive building concept with reduced technical systems for heating, ventilation and cooling. With thermodynamic simulations and a holistic view already in the conceptual design, an exemplary procedure in the field of energy efficiency should be demonstrated. Such a procedure is intended to allow forecasts of the energy requirements at an early stage of the design planning to show a common characteristic value in combination with considerations of life cycles and embedded energy. This results in a comparable value for the quantification of the total energy requirement for all possible variants of the construction – i.e. for construction as well as operation together. The respective requirements for the material of the facade and the finishing materials are connected. The project is therefore particularly suitable for the evaluation and derivation of general strategies regarding the potentials of embedded energy in the design process as well as depending on the complexity of the plant technology and the operating energy.

Resume of "Entwicklung von Strategien zur Implementierung des grauen Energieaufwands in den iterativen integrierten Entwurfsprozess von Gebäuden" Authors: Prof. Thomas Auer, Dipl.-Ing. Arch. M. Sc. Daniele Santucci, Prof. Dipl.-Ing. Ulrich Knaack, Prof. Linda Hildebrand, M.A. (Arch) Max Ernst; Martin Haas, Christian Frenzel

Full German Paper