Rapunzel Vistors Center, Legau, Germany

The program includes an exhibition area, a coffee show roastery, a bakery, and a health food store. There are seminar rooms, a cooking studio, a wine cellar and, in the reception area, a café serving its own food and drinks.

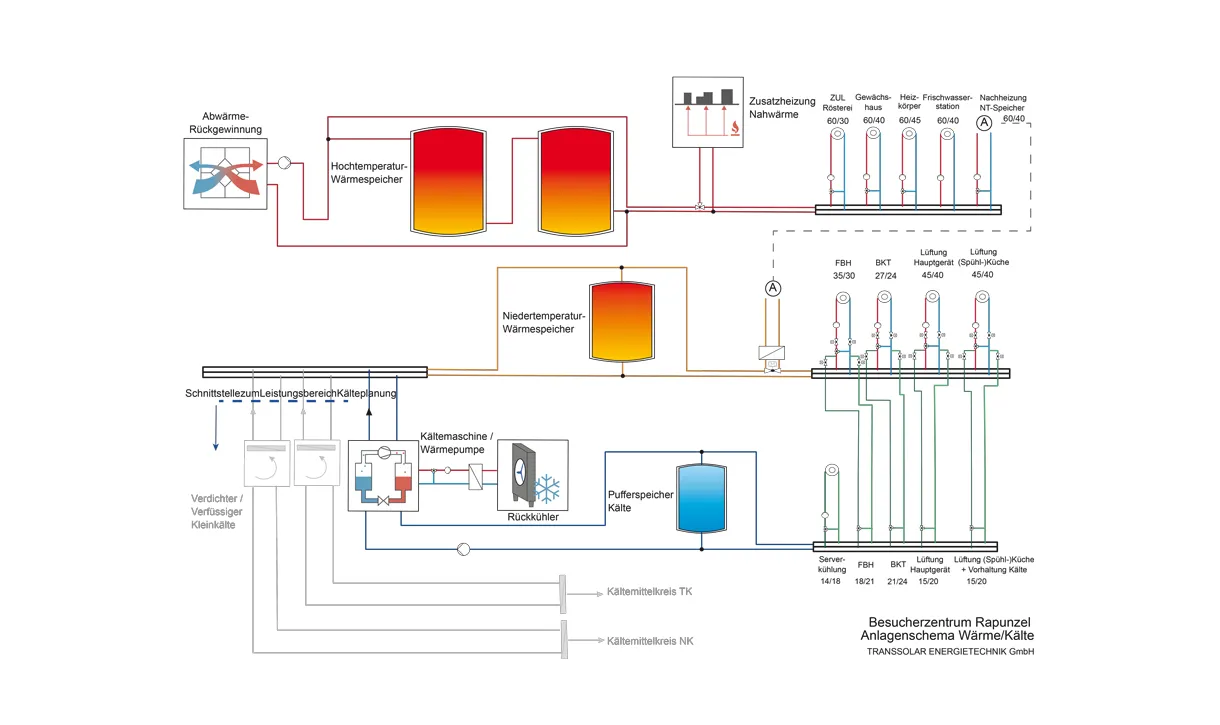

The various types of use require a ventilation and energy concept that is suitably adapted to each area. The ventilation system must properly cope with fluctuating demand, such as that caused by varying numbers of visitors. Mechanical ventilation therefore ensures the necessary basic air exchange in most areas. A control system makes it possible to ventilate the different areas individually in dependence on the actual use.

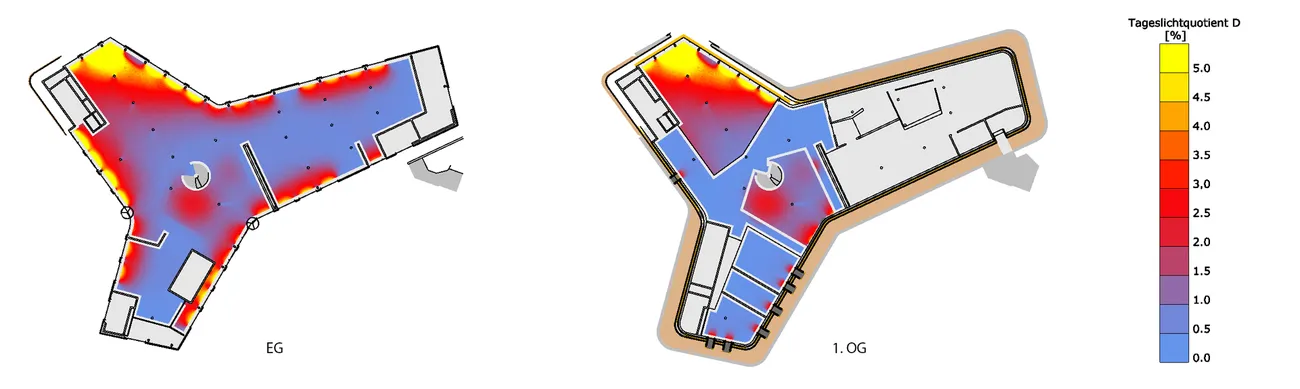

During operation, the coffee roastery has a high air requirement for the gas burners. For hygienic reasons, their supply air is fed in from outside via a separate ventilation system with fine dust and pollen filters and is preheated in an air heater in winter. The cooking studio and the seminar room on the upper floor can be easily ventilated via windows. For the summer, there is an additional possibility in the entire ground floor, as well as in the office and seminar rooms, to cool down the rooms by nightly flow of fresh air, which allows very good comfort even on hot days. Underfloor heating is used for heating in most areas. The exhibition, atrium and seminar room on the upper floor are heated and cooled via an active slab.

During operation of the roasting plant, waste heat is generated by roasting and by thermal post-treatment with gas burners, which is normally discharged via the exhaust gas system. With an annual roasting quantity of 300 t of coffee, a waste heat quantity of more than 140 MWh is generated. The center's heat demand is 110 MWh/a.

Transsolar has therefore proposed a recovery of the waste heat from the roasting waste gas to be used for heating. The percentage of the building's total heat demand that the waste heat covers depends on the roastery's operations. During some winter days, additional heat from the Rapunzel wood-fired power plant may be needed; in summer, more waste heat is generated than can be used in the building. A local heat conduction connects the new building with the production building; the waste heat from the visitor center can thus potentially also be used in production. The roastery's exhaust heat exchanger transfers the heat to two 5 m³ (177 ft³) buffer tanks that serve all consumers, first and foremost the greenhouse, the kitchen's hot water preparation, and the reheating of the low-temperature circuits. The waste heat from the small-scale refrigeration of the cold storage houses, refrigerators and refrigerated counters, freezers as well as the server cooling is also used. As waste heat sources, they are connected to the low-temperature storage tank, which supplies the low-temperature heating circuits of the floor heating, component activation and ventilation.

With the consistent use of all waste heat potentials, up to 85% of the visitor center's heating requirements can be covered by waste heat.

2023 Global Future Design Award Gold

2023 International Architecture Award Winner

2023 London Design Awards Silver